Vertical Sump Pump

Vertical Sump Pump Parameters

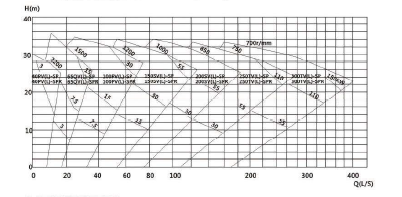

■ Flux:Q=17~1267(m³/h)

■ Lift:H=4~40 (m)

■ Motor power:W=15~200kw

■ Product standard:GB/T5656-94

Vertical Sump Pump Features

■ SP (R) type submerged pumps are vertical centrifugal slurry pump, generally into the pool or pit to work, used to transport abrasive, coarse particle, high concentration slurry.

■ Don’t need any shaft seal and shaft seal water, in the inhaled volume insufficient conditions they can also work normally.

■ SP (R) type submerged pumps’ pump body is made of wear-resisting metal. The impeller is made of wear-resistant metal or rubber, polyurethane SP (R) type submerged pumps parts into the liquid with rubber lining, they are all applicable to transport corrosive slurry. ■ All parts of the type SP(R) pump immersed in a liquid are lined with rubber. They are suited to transport the slurry which contains non-edge and acid/abrasive particles. ■ The type with “L” is a series of sump pump with an extended shaft, which is suited for the working condition of a deeper level. The guide bearing construction is added to the pump on the basis of the standard pump, so the pump is with both more steady operation and wider application range, but flushing water should be attached to the guide bearing.

Slurry Sump Pump Description

vertical suspended pump Introduction:

Type SP/SPR is Sump Pump designed for delivering abrasive, large particle, and high-density slurries. They have no need for any shaft seal and sealing water. Well operated for insufficient suction duties. Wet parts of type SP pump are made of abrasion-resistant hard alloy. All parts of type SPR pump immersed in liquid are lined with special rubber material, which is suitable for non-edge angle abrasive slurries. The depth below the liquid surface of the pumps can be customized.

Sump Pump Material

■ The pump body is made of wear-resistant metal, and the impeller is made of wear-resistant metal or rubber, polyurethane material.

Vertical Slurry Pump Working Condition

■ SP (R) type submerged slurry pumps are mainly used for handling corrosive, coarse particles and high-density slurries, and are widely used in sewage treatment, metallurgy, mining, mineral processing, dredging, dewatering, water treatment, coal washing, mill, cyclone feed, tailing, power, building material…etc. various industrial sites.

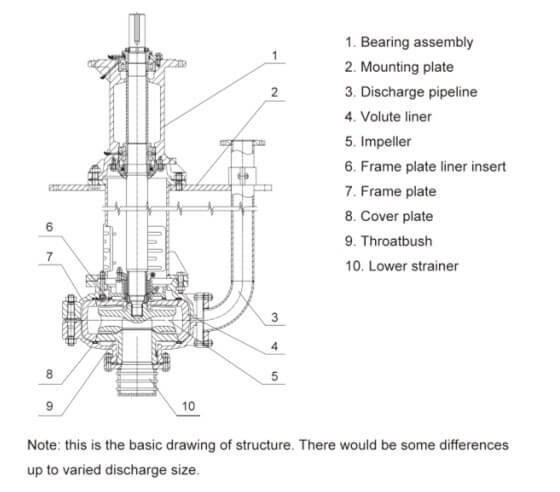

Product Structure

Working Condition